Overview

This is a new dispensing system that can apply ultra-small droplets of liquid with greater smallness, precision, and reliability to meet the needs of the manufacturing industry.

The femto-SpotterTM can transfer (apply) tiny amounts of liquid to precise positions, ranging from femtoliters (fL).

In addition, it can handle high-viscosity liquids, resolving issues that previously existed with conventional dispensers.

The femto-SpotterTM can be used alone or integrated into a system for more comprehensive applications.

Features

- Ultrafine dropletAttention

- A dispenser that can apply liquid in ultrafine amounts (fL, pL, nL) that was previously impossible.

- High-viscosity liquids

- Capable of applying various liquids with viscosities ranging from low to high (up to 200,000mPas·s).

- Accuracy

- Precise application to a specific location (position accuracy: several µm).

- Filler compatibility

- Compatible with liquids containing fillers.

- No clogging

- Since the liquid is forcibly ejected, there is no clogging.

- No dead volume

- Even expensive liquids can be used down to the last drop.

- Compact

- Also compatible with further compacting the main body.

- Customizable

- Also compatible with customizing the system.

Specifications

| Method | Needle transfer method |

| Coating volume | fL to nL* |

| Coating diameter | 5 µm to 1 mm* |

| Compatible viscosity | 1 to 200,000 mPa・s |

| Body size | 36 mm × 36 mm × 170 mm** |

| Weight | About 200 g |

* Depends on the liquid to be dispensed and the material to be coated.

** Excluding protrusions.

Mechanism Overview

The mechanism has a simple structure as follows:

- Needle: a needle that transfers liquid droplets

- Reservoir: a cylinder that holds the coating liquid

- Coating liquid: liquid to be applied by the needle is held in the reservoir

- Coating object: transfers the tiny liquid droplets adhered to the tip of the needle

The simple introduction of the mechanism is as shown in the figure on the left.

- The needle descends inside the reservoir

- The needle protrudes from the hole in the reservoir to the outside

- Tiny droplets of liquid adhering to the tip of the needle are transferred to the object surface

- The needle rises and returns to the reservoir, and moves on to the next coating

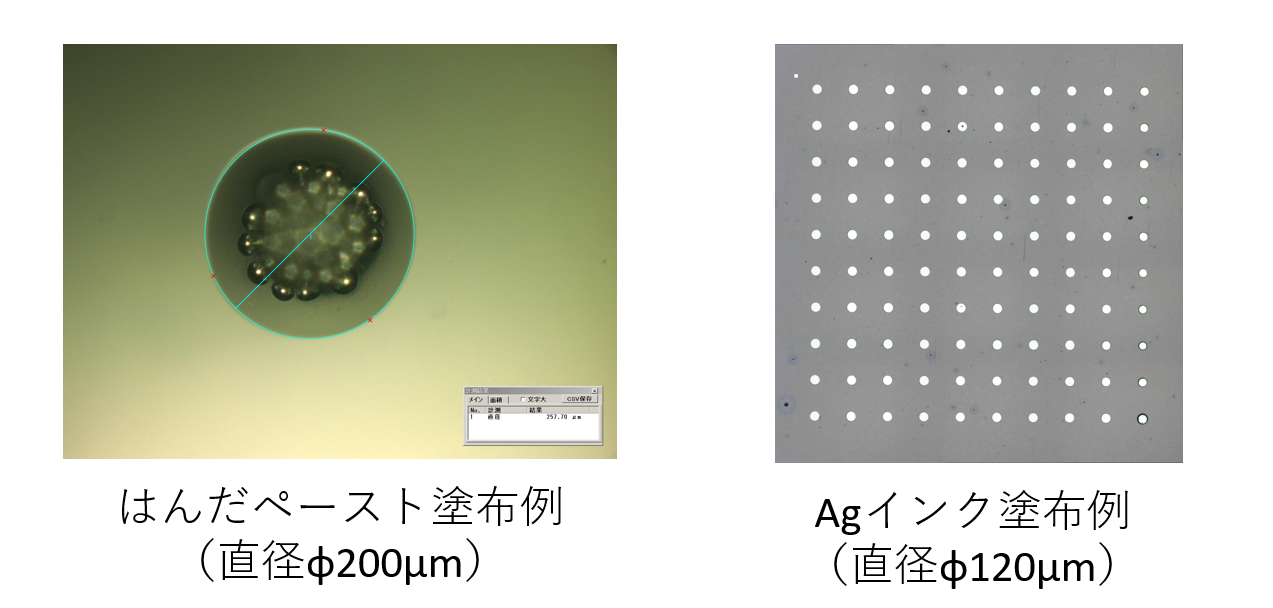

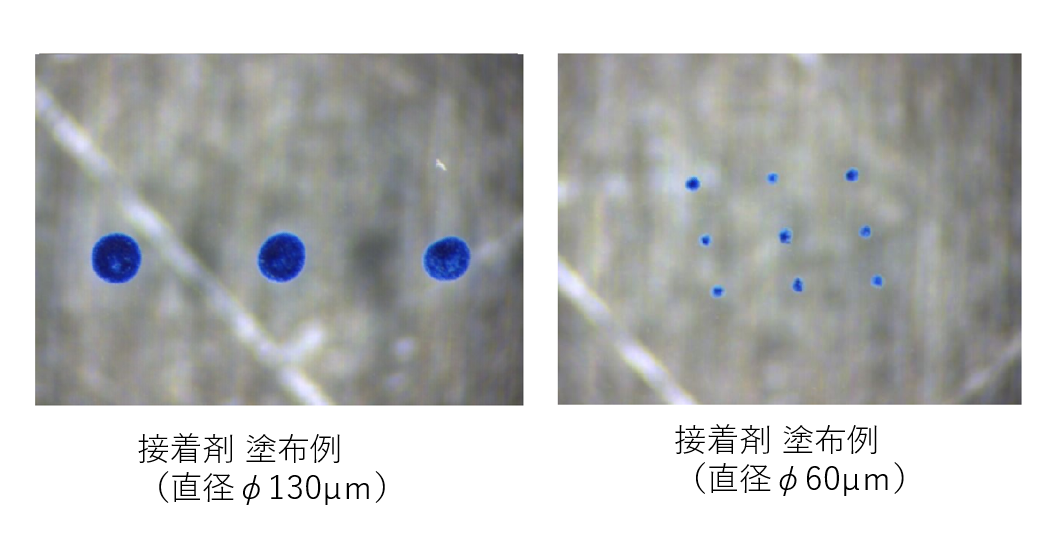

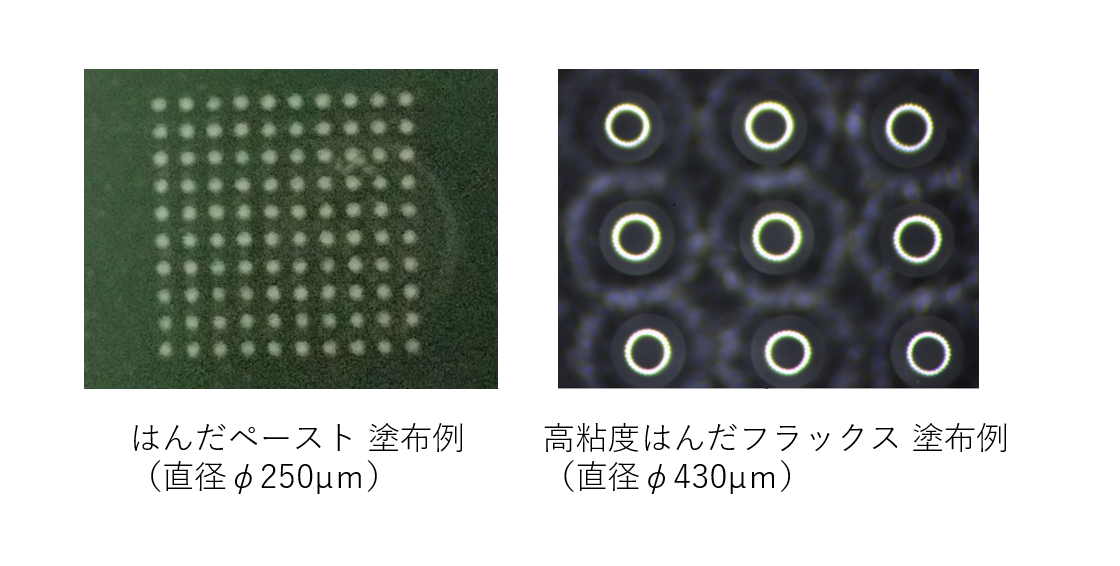

Applications

- Essential liquid control in manufacturing

- Solder paste

- Adhesives

- Ink and paint

- Also useful in research and development

- Precious liquids such as DNA and reagents

- Patterning with conductive ink

- Determination of quantitative amounts of adhesive

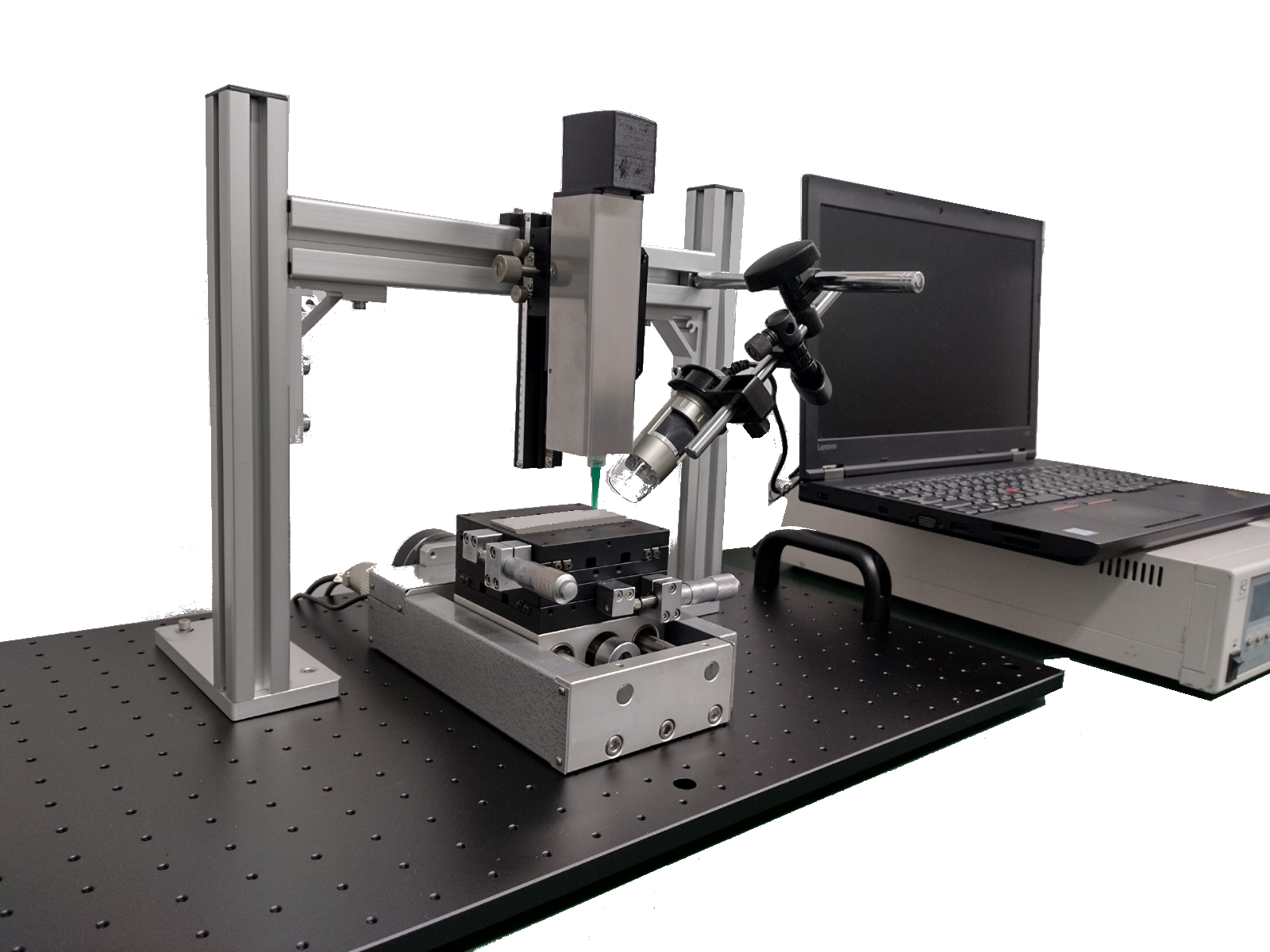

System

- From standalone head to system integration

- Prototype experiments using standalone head

- Small batch production by incorporating into a system

- Full-scale production in-line

- High-spec mass production systems are also available

- High-precision desktop system

- Batch production system