Droplet transfer mechanism – femto-SpotterTM

With advanced technology, innovative dispensers have been created. We will provide new liquid control technology by greatly improving the shortcomings of conventional dispensers.

To control the volume of fluid precisely is quite difficult but crucial for micro-machining.

femto-SpotterTM is an ultra-micro droplet transfer dispenser which is able to solve your problems at the manufacturing site.

This is a promising technology for manufacturing in future. Inquiries pour in from all over the world!

At a glance by short movie

Overview

- More smaller, more precise, more reliable. A state-of-the-art dispensing system is capable of dispensing ultra-small droplet quantities to meet the demands in the world of industry.

- femto-SpotterTM can transfer and/or apply a tiny amount of liquid to the exact position.

- The amount of liquid dispensed with femto-SpotterTM is miniscule, as small as fL (femto-liter). Moreover, it can handle high-viscosity liquids, thus solving the problems of conventional dispensers.

- femto-SpotterTM is versatile system. It can be used stand-alone or integrated into a system.

Features

| Ultrafine droplet | A dispenser that can apply liquid in ultrafine amounts (fL, pL, nL) that was previously impossible. Ranging femto-, pico-, nano-, micro-liter droplet can be transferred to substrate with changing some parameters. |

| High-viscosity liquids | Applicable to various liquids with viscosities ranging from low to high (up to 200,000mPa·s). |

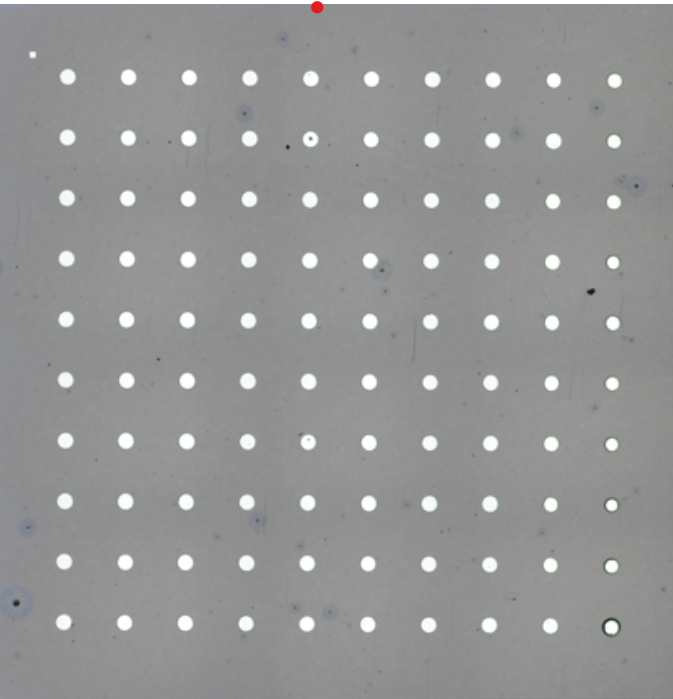

| Accuracy | Precise application to a specific location (position accuracy: several µm). |

| Filler compatibility | Liquids containing fillers are available. |

| No clogging | Pushing a needle prevents from clogging |

| No dead volume | Liquids can be perfectly used down to the last drop. |

| Compact in size | The main body is compact for embedding on other system. |

| Customize | We can offer to customize the dispenser so that it fits to your system. |

| System integrate | Desktop system, fully automated system are available. |

Comparison between dispenser type

| Tube type | Screw type | Jet type | femto-SpotterTM | |

|  |  |  | |

| Droplet size | △ > 0.1mm | × > 0.2mm | × > 0.2mm | ◎ >0.005mm |

| Viscosity | △ 1,000 mPa・s | △ 3,000 mPa・s | × 100 mPa・s | ◎ 100,000 mPa・s |

| Positoning Accucary | × ±30µm | × ±30µm | × ±100µm | ◎ ±5µm |

| Dispense speed per second | – | △ 1times ~ | ◎ ~1,000 times | 〇 several times ~ |

Specifications

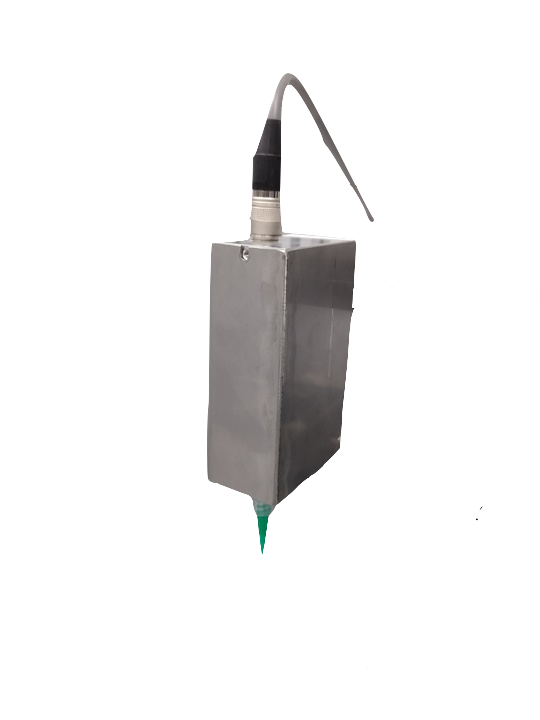

| Method | Needle transfer method |

| Volume to be dispensed | fL ~ nL* |

| Transfer diameter | 5 µm ~ 1 mm* |

| Viscosity available | 1 ~ 200,000 mPa・s |

| Dimension | 36 mm × 36 mm × 170 mm** |

| Weight | approx. 200 g |

** Excluding protrusions.

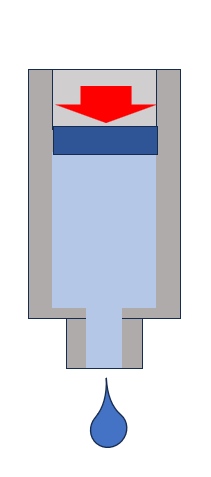

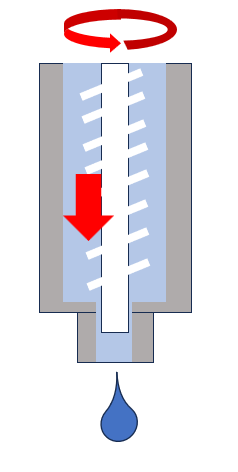

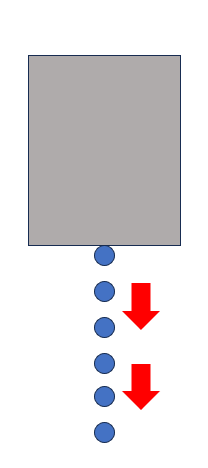

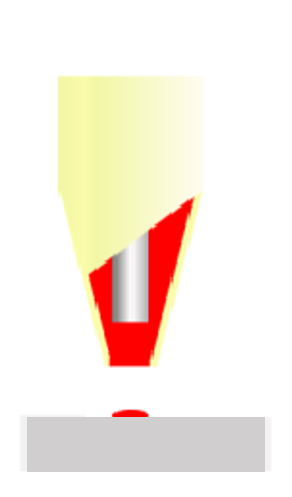

Mechanism Overview

Mechanism

- Needle: a needle that transfers liquid droplets

- Reservoir: a cylinder that holds the coating liquid

- Coating liquid: liquid to be applied by the needle is held in the reservoir

- Coating object: transfers the tiny liquid droplets adhered to the tip of the needle

Operation

- The needle descends inside the reservoir.

- The needle protrudes from the hole in the reservoir to the outside.

- Tiny droplets of liquid adhering to the tip of the needle are transferred to the object surface.

- The needle rises and returns to the reservoir, and moves on to the next coating.

Applications

- Leaflet

- Short movie : Solder paste

- Short movie : Flux

- Short movie : Tiny droplet

- Short movie : Silicon oil

Essential liquid control technology for manufacturing

- Solder paste, flux

- Adhesives

- Ink, glue, paint

- Electric conductive paste

- Resist

- Organic material

- Polymer solution

- Micro particle solution

Research and development

- Expensive and precious liquid

- Conductive ink pattering

- Controlling the liquid volume

- Nano particle solvent

- Rapid prototyping of polymer MEMs

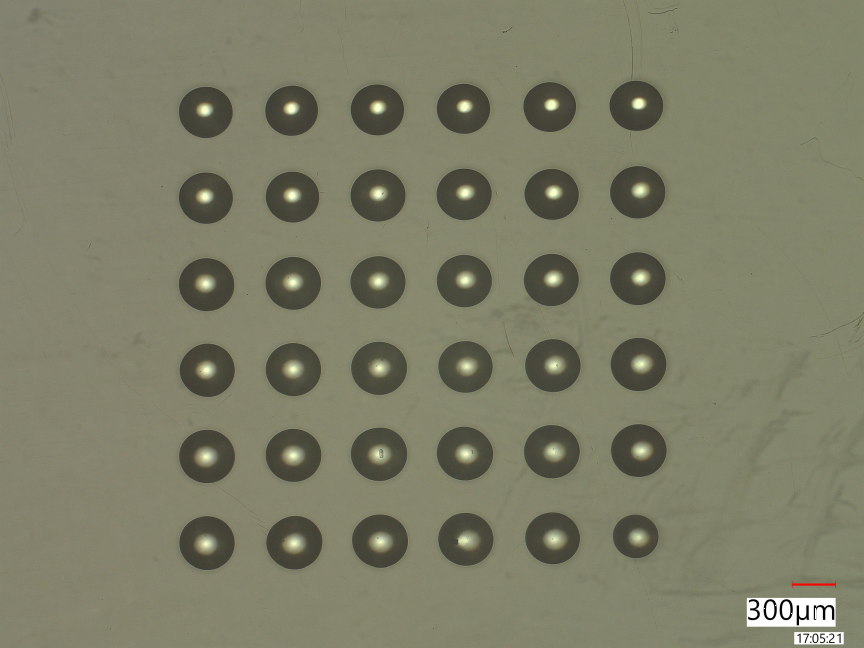

- High density optical component prototyping

- Surface curing in tiny area

- High precision coating

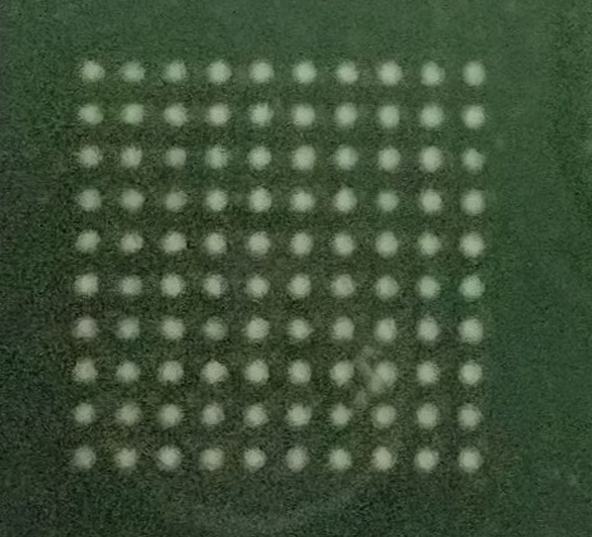

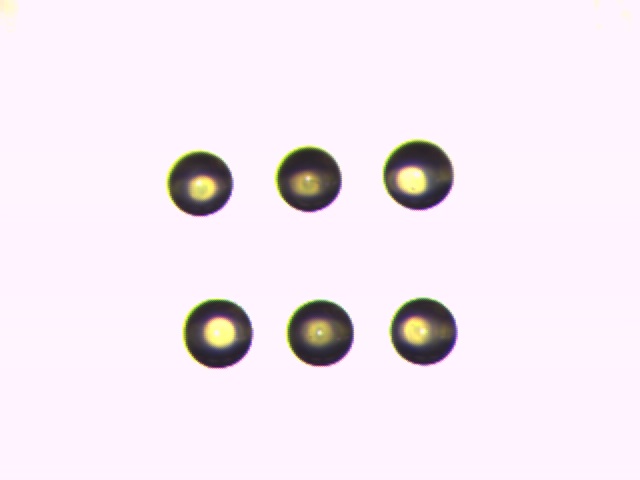

Solder paste

Dia. φ200µm

Flux

Dia. φ100µm

Adhesive

Dia. φ60µm

Ag nano ink

Dia. φ100µm

Flux

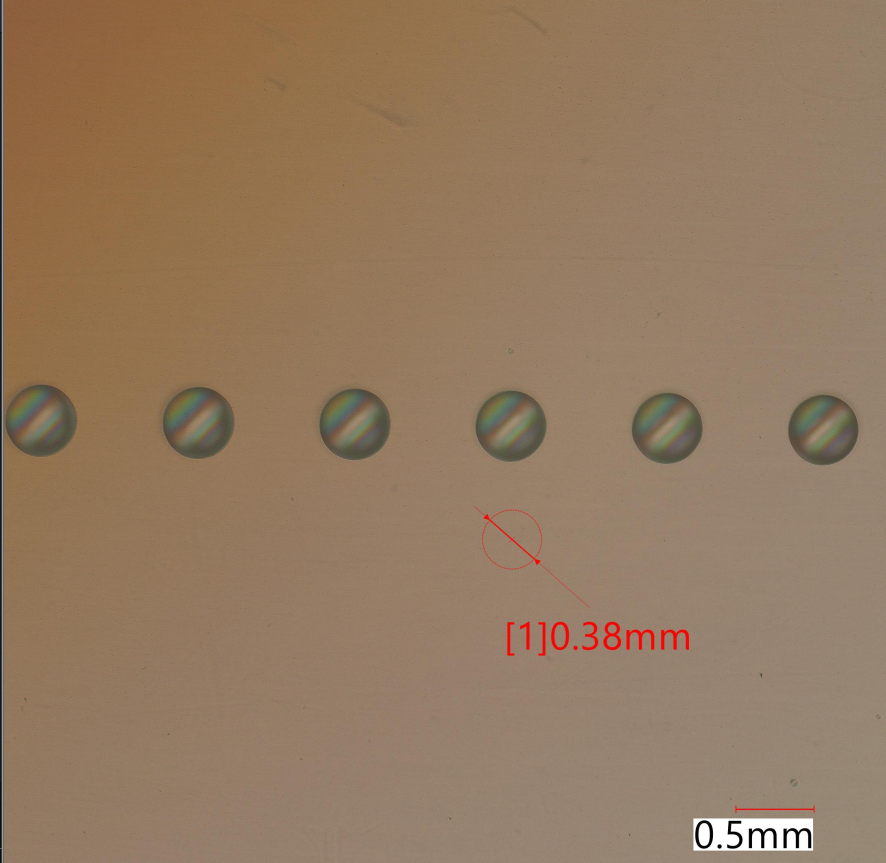

Dia. φ300µm

Glue

Dia. φ150µm

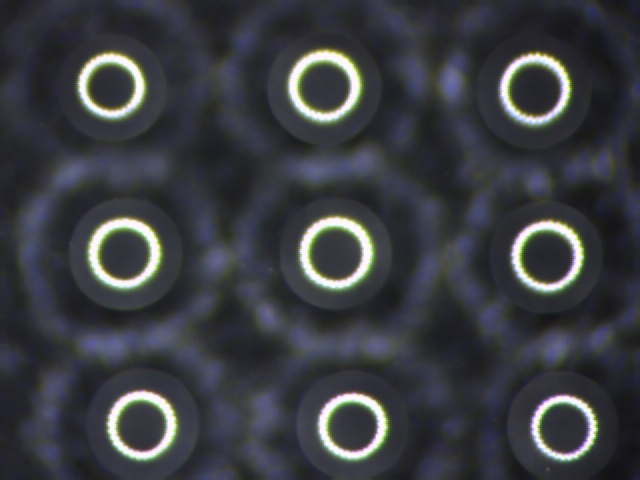

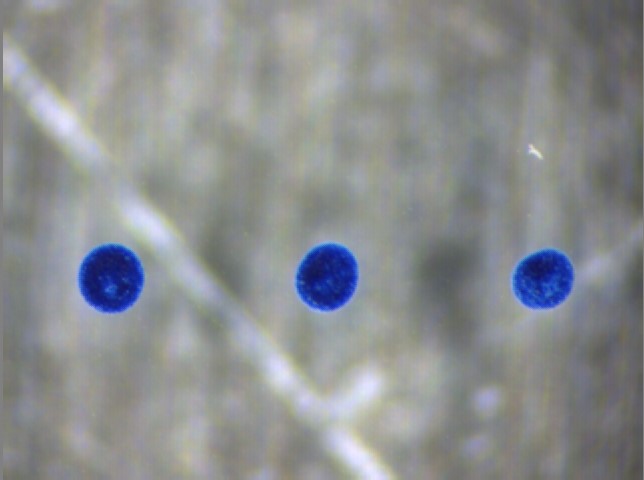

- 400um diameter droplet

- liquid : high viscous 1,000cP silicone oil

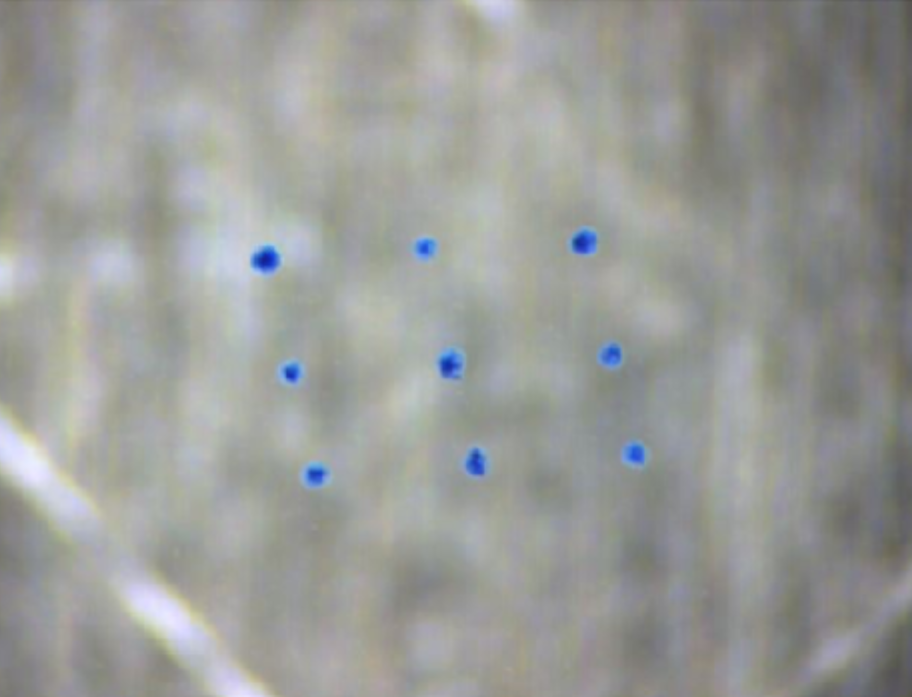

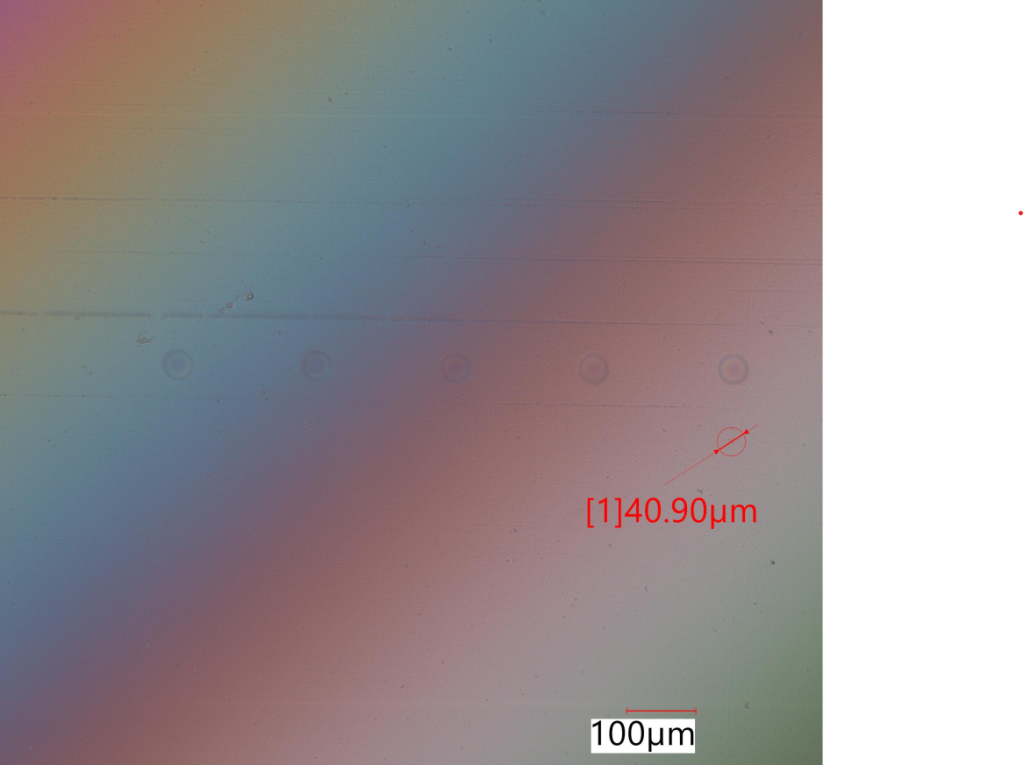

- 40um micro droplet

- liquid : high viscous 1,000cP silicone oil

- 100,000cP high viscous silicone oil

- Very small volume deviation

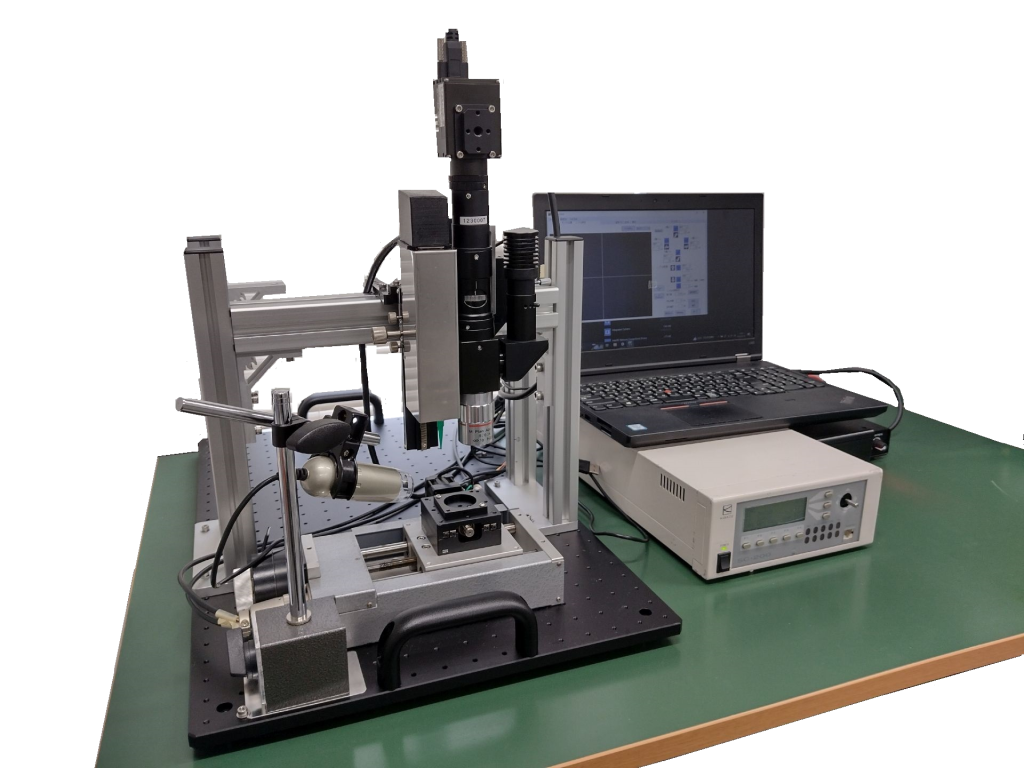

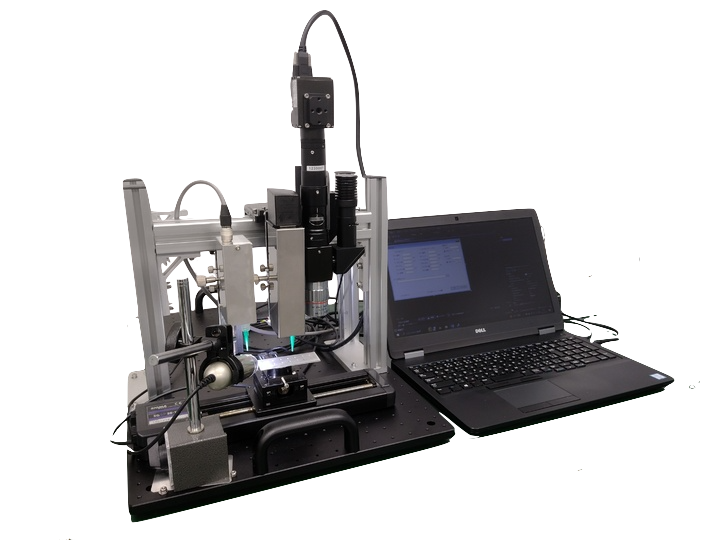

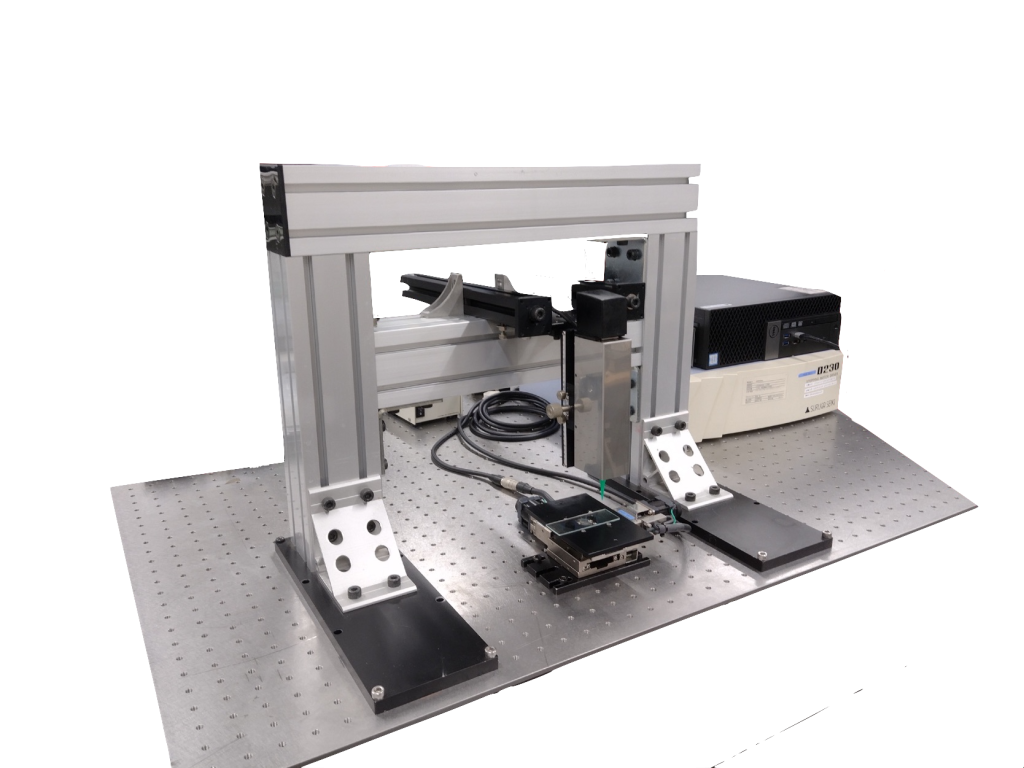

System

Dispensing head to system

- Prototype experiment using a single head

- Desktop simple system

- Small lot production integrated into the system

- Up to full-scale in-line production

- Precision dispensing system for medicine

- Volumetric dispensing ccontroller

High-spec mass production systems are also available

- High precision desktop system

- Precision Fluid Dispensing table

- Batch production system

- Mounting on chip mounters and laser cutting machines

femto-Spotter head line-up : Model A

Micro-droplet dispensing basic type

FS-100M

- Simple and basic dispensing head

- Only small volume of liquid is needed for operation

- Simple operation and big benefit

Micro-droplet long-life dispensing type

FS-100M-LL

- Suitable for long-life processing

- Stable operation in long-run

- The best solution for process development

femto-Spotter head line-up : Model B

Micro-droplet dispensing basic type

FS-200M

- More compact and more reliable

- Easy to operate

- Long term stability

Micro-droplet long-life dispensing type

FS-200M-LL

- Long term liquid supply function is possible

- Easy and stable operation for high viscous liquid

- Ideal system for industrial purpose

Micro-droplet dispensing high-speed type

FS-300M

- High-speed dispensing

- Improve your productivity

- High viscous liquid

- ultra small volume dispensing

Temperature control module

- Best solution for precise dispensing

- Room temperature to 100 ℃

- Resolution : 0.1 ℃

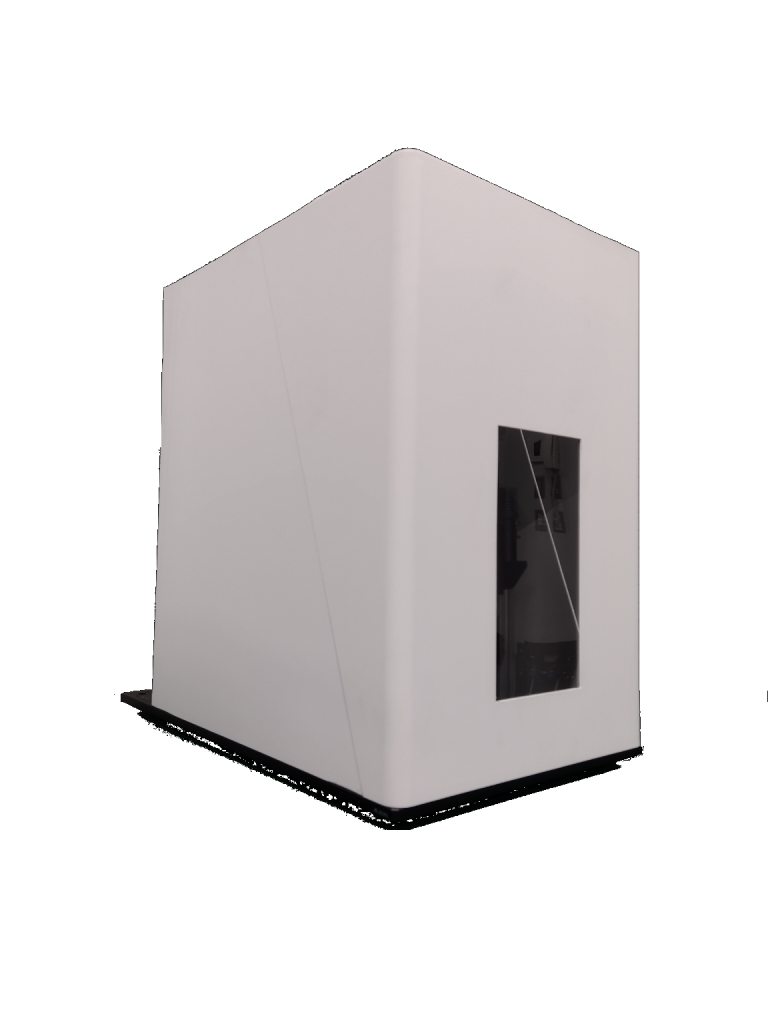

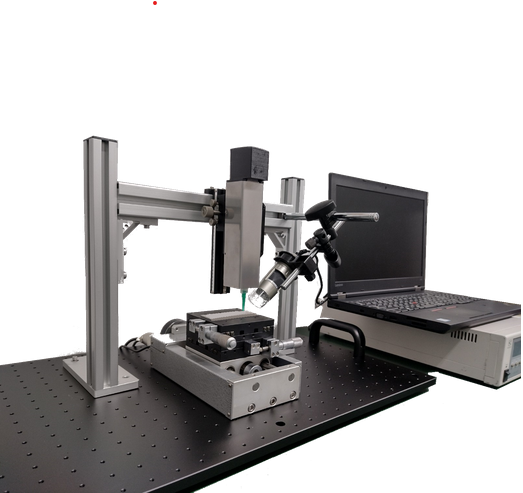

femto-Spotter Desktop dispensing system:

Simple dispensing type

FS-100M-sysD

- Simple installation for quick start

- Feel the high capability of the system

- Material evaluation, substrate verification

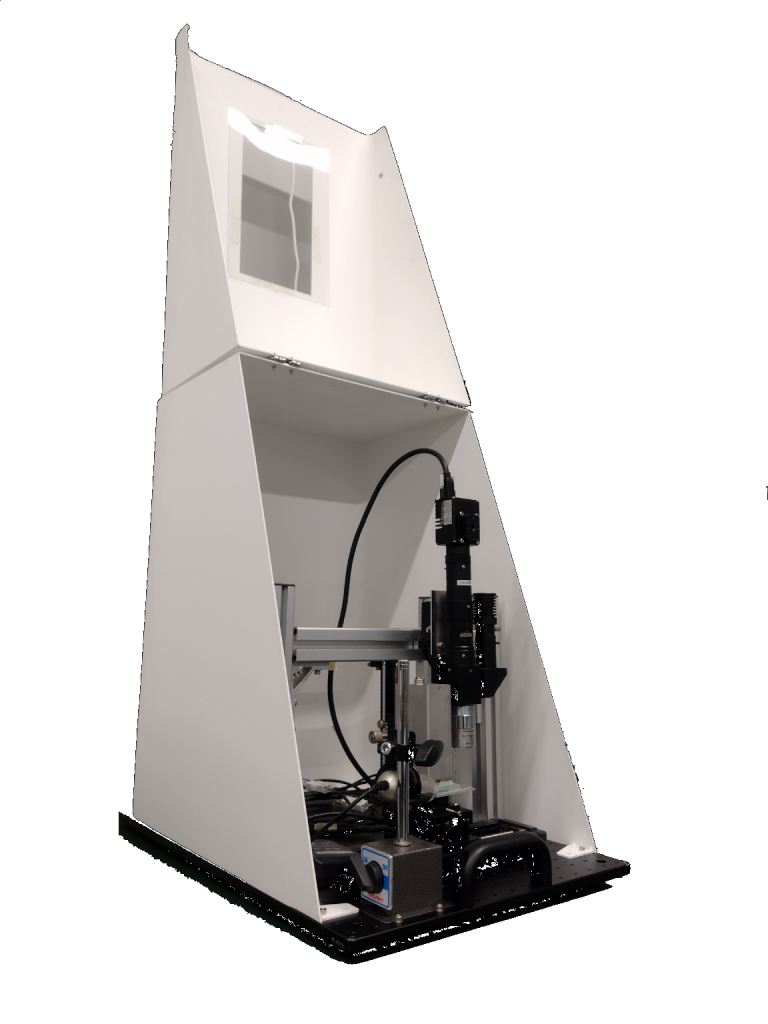

High precision dispensing type

FS-100M-sysDA

- Integration of high precision vision system

- Good alignment for precise spotting

- Automatic dispense-sensing feature

- Excellent dispensing result with versatile program software

Dual dispensing type

FS-100M-sysD-Dual

- Dual dispensing head system

- High accurate dispensing positioning

- Easy liquid exhange

High rigidity dispensing type

FS-100M-H

- High rigidity frame type

- Stable dispensing over time

femto-SpotterTM is the best solution for liquid additive micro processing in the world.

Demonstration with your liquid and substrate are welcomed anytime.